What are the different types of HVAC circulating pumps and how do they differ in terms of design and functionality?

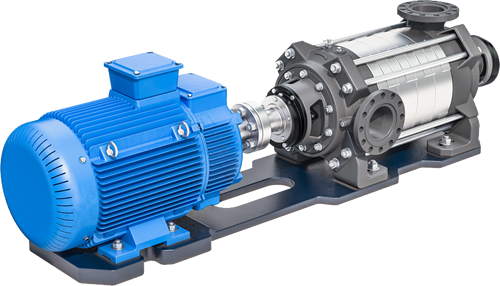

There are several types of HVAC circulating pumps, including inline, end suction, split-case, and multistage pumps. Inline pumps have a single volute and are typically used in small to medium-sized systems, while end suction pumps have a double volute and are often used in larger systems. Split-case pumps have a split casing and are used in large systems with high flow rates, while multistage pumps have multiple impellers and are used in high-pressure applications. Each type of pump has unique design and functionality features that make it well-suited for specific applications.

What are some common problems that can occur with HVAC circulating pumps and how can they be prevented?

Some common problems that can occur with HVAC circulating pumps include leaks, worn bearings, damaged impellers, clogged filters, and electrical problems. These issues can be prevented by scheduling regular maintenance and HVAC circulation pump service, including inspections, lubrication, cleaning, and replacing worn or damaged parts. It is also important to monitor the system for any changes in performance or energy consumption, which can indicate a problem with the pump.

What are the energy efficiency considerations when selecting an HVAC circulating pump?

One key efficiency and energy consideration is the HVAC circulator pump's motor efficiency, which can impact the overall energy efficiency of the system. Additionally, selecting a pump with a variable speed drive (VSD) can help to reduce energy consumption by allowing the pump to operate at a lower speed when demand for heating or cooling is lower. It is also important to select a pump that is appropriately sized for the specific application, as an oversized or undersized pump can lead to energy waste and decreased efficiency.

How can I ensure that my HVAC circulating pump is operating efficiently and not wasting energy?

Appropriately matching the pump size appropriately with the specific application it’s needed for can help to increase energy efficiency and reduce waste. Additionally, regular HVAC circulating pump maintenance and monitoring can help to ensure that your unit is operating efficiently and not wasting energy. This should include monitoring energy consumption, checking for leaks, ensuring proper alignment and balance, and replacing worn or damaged parts.

Goulds

Goulds