Cooling towers are an essential component of commercial and industrial HVAC systems. They differ in size and design, depending on the scale of a project, the layout of a building, and the humidity levels of a location.

But, what does a cooling tower do? An HVAC cooling tower is a heat exchanger that brings air and water together to reduce the temperature of water through evaporation. As a result, cool air is circulated within buildings to keep its occupants comfortable while they work or to keep operational equipment at desired temperatures.

Since HVAC cooling towers are kept on the roofs of buildings, they can often fall into disrepair if neglected. It’s important to maintain an HVAC cooling tower by keeping an eye on expensive machinery that could malfunction over time.

In the next sections, we dive into how cooling towers work, the essential components of a cooling tower, and how to maintain this crucial piece of equipment.

Certain HVAC cooling towers are part of refrigeration systems that circulate cool air in areas where crucial industrial activities happen indoors. Other kinds of HVAC cooling towers are used to maintain comfortable temperatures within large commercial spaces. Below you’ll find some of the most common applications of an HVAC cooling tower:

Cooling Tower Commercial Applications

Clinics, hospitals, laboratories, office buildings, hotels, schools, universities, airports, malls, leased workspaces, nursing/old-age homes, storage facilities, and shopping complexes

Cooling Tower Industrial Applications

Clinics, hospitals, laboratories, office buildings, hotels, schools, universities, airports, malls, leased workspaces, nursing/old-age homes, storage facilities, and shopping complexes

To understand how HVAC cooling towers work, it’s important to understand the integral components that make up the whole. As we explore each component, the answer to “how does a cooling tower work?” will become clearer.

Water Distribution

A condenser pump (pumps condensate water from a cooling system) delivers hot water (converted from hot air released by air-conditioning and industrial units) to the top of an HVAC cooling tower via its distribution piping. This hot water moves through nozzles in an open cooling tower before it is deposited on a heat transfer medium called a fill. Water collects in a cold-water collection basin at the base of the unit after it moves through the fill. This cool water is then recirculated to the condenser to complete the cooling loop.

Since the water of an open cooling tower is exposed to outdoor air, it may attract contaminants. Hence, a fluid filtration system is installed to ensure that clean water is continuously circulated through the cooling tower.

In a closed-loop tower, water from a condenser loop moves through the tubes in the unit without coming into contact with outside air. For this type of cooling tower, condensate water circulates only within the tubes of the unit. The condensate water cools down while moving through the piping of the tower before cool air is released.

Heat Transfer Medium or Fill

An HVAC cooling tower releases waste heat through evaporation. Hot water from a condenser is slowly distributed and spread on a fill to encourage heat between air and water, causing the liquid to evaporate. As the hot water gradually evaporates across the fill or concealed circuit tubes, it cools down and converts into cool water vapor. Cold water is then recirculated back to the heat exchanger to absorb more heat and continue the process in a loop. Cool air is then distributed within a building.

Air Circulation

The more air moving through the fill, the higher the rate of evaporation and cooling within an HVAC cooling tower. Fans or blowers generate airflow at varying speeds depending on the size of the HVAC cooling tower, the temperature of condensate water, flow rate, and other factors. Variable speed drives, or VSDs, are installed with fan motors to control the speed and temperature of the water as it exits the cooling tower.

Drift Eliminator

Installing a drift eliminator keeps moisture contained within a cooling tower. Drift eliminators prevent droplets of cool water and mist from escaping from an HVAC cooling tower. Without a drift eliminator, water will escape and fall onto surfaces or people that sit under or close to cooling vents. The drift water contains minerals or chemicals that should ideally be nowhere near people or machinery.

Edison Parker is a leading provider of different types of cooling and heating systems as well as mechanical replacement parts. We build and install a fine line of state-of-the-art HVAC cooling tower systems for commercial and industrial properties in New York and its five boroughs, and the tristate area.

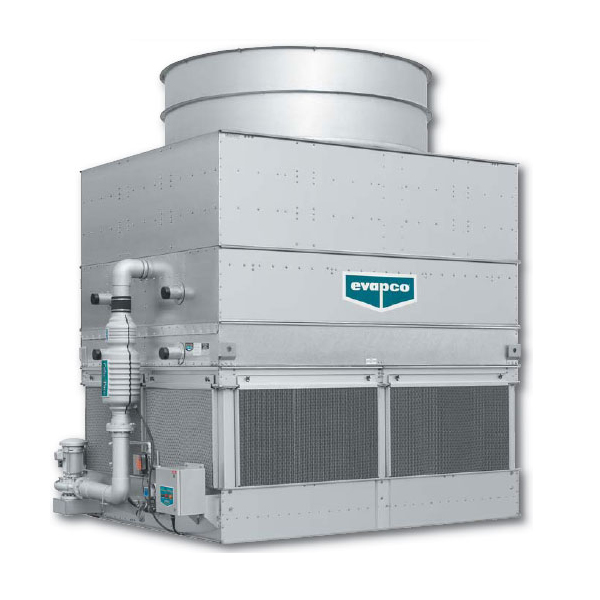

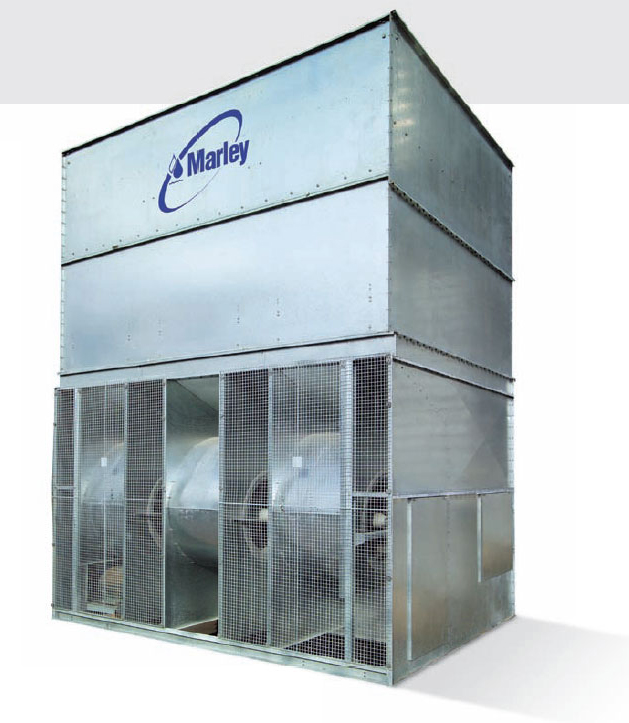

Take a look at these popular HVAC cooling towers that have stood the test of time and performed beyond the expectations of our clients.

FXT cooling towers are known for consuming less energy. Building owners can enjoy lower energy costs and can conserve natural resources with this type of cooling tower. FXT units require less maintenance and can be installed faster, making them an ideal choice for HVAC for large buildings.

Closed circuit cooling towers or evaporative fluid coolers are a contaminant-free alternative since cooling happens within a closed loop. They often work in conjunction with a heat pump where closed-loop cooling is needed. Depending on the scale of the cooling tower a commercial building needs, closed-circuit cooling towers can be a space-saving, reliable, and cost-effective cooling solution. Modifications can be made to the cooling towers based on your needs to ensure peak system performance.

These cooling towers are perfect for those who need quiet performance. Unlike traditional cooling towers, MCW units take up considerably less floor space. Low-clog nozzles, noiseless enclosed parts, and lower consumption make MCW cooling towers ideal for commercial and industrial applications.

Single-cell unit cooling towers feature a one-sided air inlet design that makes them easily fit into tight spaces. These cooling towers require less energy, are low maintenance, and have low cooling tower operation costs, making them a highly efficient solution for large buildings and facilities.

Maintaining a cooling tower should be a priority so you can save on unnecessary hefty repair and replacement costs. On-site personnel should perform regular maintenance checks to ensure that cooling towers are working at optimal levels.

Maintaining an HVAC Cooling Tower

Proper Contamination and Cleaning

Water can sit for long periods in a cooling tower, which can make it a breeding ground for bacteria. The interior of the HVAC cooling tower should be disinfected and cleaned thoroughly to eliminate bacterial growth. Equipment such as power washers, chemical solvents, and vacuums can help flush out and get rid of grime and dirt. Cleaning cooling towers regularly is imperative to avoid an outbreak of legionella bacteria, an organism that causes mild flu-like or pneumonia-type symptoms.

Water Treatment

An HVAC cooling tower can run into trouble if it isn’t supplied with quality water. The last thing you need is for contaminated water to disrupt operations. Perform regular water treatment processes according to the instructions of your unit’s manufacturer.

Component Inspections

The mechanical and electrical components of a cooling tower need regular inspection and servicing. These checks ensure continuous operation and prevent inconvenience to your workforce. Parts such as fans, blowers, motors, belts, wiring, and capacitors should be checked weekly or monthly for irregularities.

Clean Out Scale Deposits

Scale deposits are built-up minerals from evaporated water that bind together and stick to the insides of HVAC cooling towers. Not eliminating scale deposits regularly can hamper the efficiency of a cooling tower. This process is usually performed two to three times a year to avoid limescale buildup.

The cost of an HVAC cooling tower depends on several factors such as its placement, weight, and size. The best way to find out how much an HVAC cooling tower costs is to contact us, but to give you a rough estimate, it can cost between $120 and $200 per ton. The average price for cooling tower systems can fall anywhere between $50,000 and $200,000 (and sometimes more), depending on the model, make, and horsepower per ton ratio of the unit.

Replacing a commercial cooling tower will depend on if the cold-water collection basin is unable to support the tower’s structure anymore due to age or damage. If the repair cost is significantly higher (more than 60% ) than the cost of a new unit, it’s best to replace the cooling tower. You’ll have to consider other factors as well, like the cost of repairing faulty parts (and if replacing these will be smarter) or relocation services. Commercial HVAC repair companies like Edison Parker can help you decide whether an existing building cooling tower needs to be repaired or replaced after a detailed evaluation.

Commercial and industrial buildings invest in HVAC cooling towers to support a structure’s energy production or industrial system. An HVAC cooling tower can be found on top of tall buildings and is generally part of its heating, ventilation, and air conditioning system. HVAC cooling towers are kept on flat rooftops or in restricted outdoor locations accessible only to authorized personnel.

Edison Parker’s team of experts can perform routine evaluations and disinfection procedures. Building owners should ideally approach a company that performs these processes in compliance with the American Society of Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE) Standard 188P and Cooling Technology Institute (CTI) Guidelines WTB-148.

Now that you know how a cooling tower works, it’s clear how important HVAC units are for commercial buildings. Edison Parker strives to deliver unparalleled services for the best heating and cooling solutions in New York and nearby areas for its clients. Contact us today at 718-768-1600.