Cooling Tower Controls

Cooling tower controls are an essential component of any cooling tower system. These controls help to regulate the operation of the cooling tower, ensuring that it operates efficiently and effectively. Cooling tower controls can include a variety of components, such as control panels, sensors, and valves, which work together to control the flow and temperature of the water in the cooling tower.

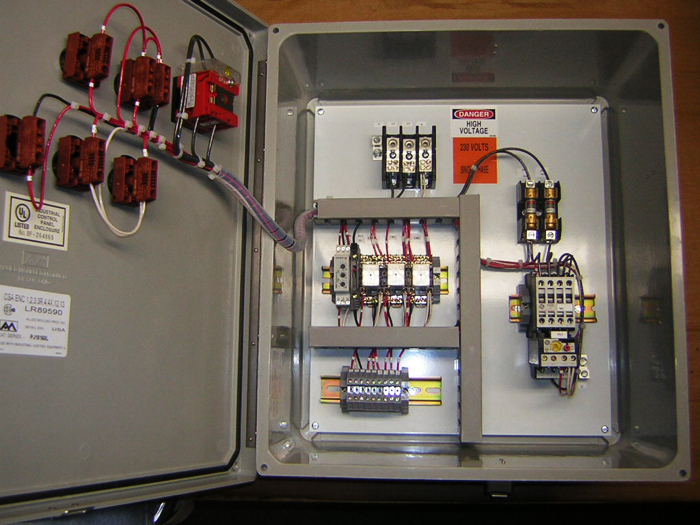

Cooling Tower Control Panel

A cooling tower control panel is the central hub of the cooling tower control system. It houses the control logic and interfaces that allow operators to monitor and adjust the operation of the cooling tower. The control panel may include features such as temperature displays, flow rate indicators, and alarm systems to alert operators to any issues with the cooling tower.

Cooling Tower Control Strategy

The cooling tower control strategy is the plan or approach used to control the operation of the cooling tower. This strategy may involve adjusting the flow rate of the water, controlling the fan speed, or regulating the temperature of the water to achieve the desired cooling effect. The control strategy is typically designed to optimize the efficiency of the cooling tower, reducing energy consumption and minimizing wear and tear on the cooling tower components.

Cooling Tower Control Sequence

The cooling tower control sequence is the order in which the various components of the cooling tower control system operate. For example, the control sequence may start with the activation of the water pump, followed by the activation of the cooling tower fan, and then the opening of the cooling tower control valve. The control sequence is designed to ensure that the cooling tower operates smoothly and efficiently, with each component working in harmony with the others.

Cooling Tower Control System

The cooling tower control system is the overall system that controls the operation of the cooling tower. This system includes all of the control components, such as the control panel, sensors, and valves, as well as the control logic and control strategy. The control system is designed to ensure that the cooling tower operates efficiently and effectively, providing the desired cooling effect while minimizing energy consumption and wear and tear on the cooling tower components.

Cooling Tower Control Diagram

The cooling tower control diagram is a visual representation of the cooling tower control system. It shows the layout of the control components and the connections between them. The control diagram can be a useful tool for understanding how the control system works and for troubleshooting any issues with the cooling tower controls.

Cooling Tower Control Logic

The cooling tower control logic is the set of rules or algorithms that govern the operation of the cooling tower control system. This logic determines how the control components interact with each other and how they respond to various conditions in the cooling tower. The control logic is typically programmed into the control panel and can be adjusted as needed to optimize the operation of the cooling tower.

Cooling Tower Control Valve

The cooling tower control valve is a key component of the cooling tower control system. This valve regulates the flow of water through the cooling tower, allowing operators to control the amount of cooling provided by the tower. The control valve is typically controlled by the control panel, which adjusts the valve position based on the control logic and the current conditions in the cooling tower.

Cooling Tower Control Wiring Diagram

The cooling tower control wiring diagram is a detailed diagram that shows the electrical connections between the various components of the cooling tower control system. This diagram can be a useful tool for installing, troubleshooting, or repairing the control system.

Cooling Tower Control Wet Bulb Temperature

The cooling tower control wet bulb temperature is a measure of the temperature of the air in the cooling tower, taking into account the humidity of the air. This temperature is a key factor in the operation of the cooling tower, as it affects the rate of evaporation and the cooling effect of the tower. The control system monitors the wet bulb temperature and adjusts the operation of the cooling tower accordingly.

Cooling Tower Controls Service

When it comes to cooling tower controls service, it is important to work with a qualified service provider who has experience with cooling tower control systems. Regular maintenance and inspection of the control system can help to ensure that it operates efficiently and effectively, reducing energy consumption and minimizing wear and tear on the cooling tower components.

Buy Replacement Cooling Tower Controls

If you need to buy a replacement for your cooling tower controls, it is important to select a control system that is compatible with your cooling tower and that meets your specific needs. The control system should be designed to optimize the efficiency of your cooling tower, reducing energy consumption and minimizing wear and tear on the cooling tower components.

Cooling Tower Controls Maintenance

Regular cooling tower controls maintenance is essential for the efficient and effective operation of your cooling tower. This maintenance may involve inspecting and cleaning the control components, checking and adjusting the control logic and control strategy, and testing the operation of the control system.

Cooling Tower Controls Repair

If your cooling tower controls require repair, it is important to work with a qualified service provider who has experience with cooling tower control systems. The service provider should be able to diagnose the issue, recommend the appropriate repair or replacement options, and carry out the necessary repairs to get your cooling tower back up and running.

718.768.1600

718.768.1600