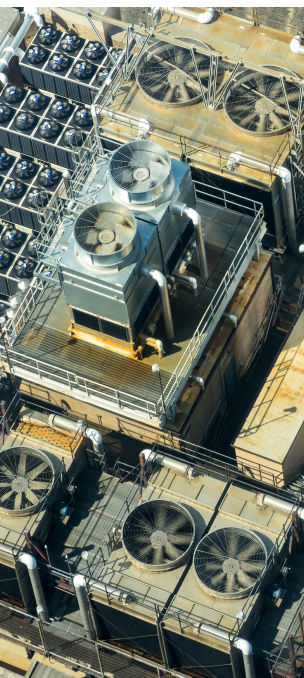

Cooling towers are considered a heat rejection device, which means they get rid of heat by use of a machine or process — or both. You might see them in the form of huge towers or large, bulky machines. The type of cooling tower an area needs depends on the area being cooled and the type of activity which takes place within that space. There may also be zoning and other government regulations related to what type of cooling towers you need and when.

Typically, you’ll find commercial cooling towers on buildings like oil refineries, manufacturing plants, hospitals, petrochemical and other chemical plants, nuclear power stations, and the like. If you have a process related to energy you’re likely going to need some type of cooling towers, though the size of your cooling tower will depend on the type of operation you run.

Edison Parker sells, maintains and services cooling towers all over New York and New Jersey, for both small and large operations. With large, commercial buildings generally consisting of large HVAC systems, those cooling towers are essential to keep the system running right: Cooling towers work overtime in industrial spaces to keep all systems running smoothly.

There are several factors you need to think about when it comes to choosing a cooling tower. The first is to make sure that it’s the right size for your operations so that your facility is well taken care of. If you get a product that is too big, you’re expending energy for a cooling tower you don’t need. On the other hand, if your cooling tower is too small, chances are you’ll overwork the system and require extensive and expensive repairs. cause premature break, or expen you get something too small you could end up hurting the entire system, which is going to mean lots of expensive repairs.

Maintenance is crucial for your cooling equipment’s health. The key here is to hire a professional cooling tower repair service near you that can get the job done quickly and easily. This is especially true with descaling and with clearing out the tubes.

Remember there are miles of tubes throughout your HVAC system and if one spot is missed, that can end up causing problems to the entire system.

There are several different types of cooling towers that cool mechanical systems you should consider when you are looking to set up your system. These are crossflow, counterflow, and hyperbolic. You can also look at airflow varieties, which come in induced draft and passive draft.

Let’s take a look at each one and see how each one is unique:

These values allow you to calculate the NPSHa (Net Positive Suction Head available) of the setup which will allow you to choose the most suitable pump.

Here are some components you want to look at to make sure you’re getting a quality cooling system that is the right size for your needs:

There are several aspects involved in caring for cooling towers and it starts with keeping the entire thing clean. This is going to be the most important step, because it means everything else that happens within (or around) the tower is going to be much easier.

Removing scale deposits, or calcium deposits, is considered essential, as there are plenty of minerals in the water used in the cooling tower system. These will cause limescale buildup — which can cause the system to start breaking down. This is because the limescale affects the mechanical components, rendering them less effective.Eventually this can lead to complete malfunction.

Monitoring air flow is another important aspect because improper air flow is going to reduce your efficiency. If this goes on for a long time, blocked airflow can even cause an entire cooling system to break down. Many things, including scale and debris falling into the cooling tower could interrupt your air flow so make sure you’re checking if you notice a problem.

Next, chiller tubes, which contain the refrigerant in the cooling tower, need to be fully cleared at all times. Much like the drains in your home, you need your chiller tubes to be free of anything that could interfere with the flow. They can attract mud, algae, scale deposits and slime, so make sure you’re checking frequently and removing debris.

The water pump in the mechanical room or near the chiller tubes, needs to be working properly in order to keep everything else going. Make sure you maintain the pump to keep the operations as simple as possible. The easier it is for the pump to work the more efficient it’s going to be.

Finally, make sure the water is properly treated and that you have the right water quality throughout your system. The water is used as a coolant to cycle through the tower (depending on the specific type that you have) and keep the components at the right temperature. It must be treated through the removal of dirt, debris, scale, and other particles that can get into it throughout the process of cycling through. It also must be replaced frequently as water is lost through the process of evaporation, blow-through, draw-down, and others.

If you don’t treat the water properly on a consistent basis, those problems with debris and limescale are going to build up consistently over time in an unhealthy way, and that’s going to cost you time and money.

In general, the best way to increase your efficiency is to make sure that your cooling tower is operating at full power and isn’t being blocked anywhere along the way. Working with a cooling tower repair service will help you to keep your tower working right.

How Often Should You Clean a Cooling Tower?You will want to hire aa hire cooling tower repair company at least twice per year to make sure that your system is working right and is completely clean and clear. If you have any problems with the tower or it doesn’t seem to be efficient then you may want to look for a professional cooling tower maintenance service.

How Much Water Does a Cooling Tower Use?While the amount could vary slightly, you’ll generally find that a cooling tower uses 2.4 gallons of water per minute per 100 tons of cooling just in evaporation.

How to Calculate Cooling Tower Efficiency?You’ll need a little bit of math skill in order to calculate the cooling tower efficiency or how much quality you get from the energy it uses. In general, you will take: Range/(Range+Approach)x100 Or you can take: (Hot Water Temperature-Cold Water Temperature)x100/(Hot Water Temperature-Wet Bulb Temperature)