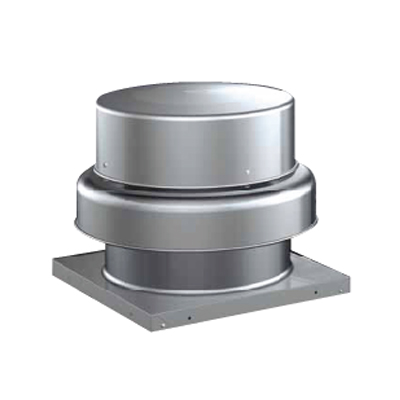

A Centrifugal Inline Fan is a type of fan that is commonly used in various commercial and industrial settings. These fans are known for their high efficiency, low noise levels, and smooth operation. They are designed to move air along the axis of the fan, which is different from axial fans that move air along the axis of the fan. This makes them ideal for applications where a high pressure is required, such as in ventilation systems, HVAC systems, and industrial processes.

Centrifugal Inline Fans are designed with an impeller that consists of a number of blades mounted around a hub. The air enters the fan wheel through the housing inlet, turns 90 degrees and is accelerated radially and exits the fan housing. They are capable of moving large volumes of air against high pressure resistance, and they are highly efficient in energy consumption.

Centrifugal Inline Fans are often used in applications such as air conditioning systems, heating systems, ventilation systems, and industrial processes. They are also used in commercial buildings, factories, and other large facilities where a large volume of air needs to be moved.

Applications of Centrifugal Inline Fans : Centrifugal Inline Fans are versatile and can be used in a variety of applications. Here are some common uses:

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, Centrifugal Inline Fans are used to circulate air throughout the building. They help in maintaining the indoor air quality and temperature by removing stale air and replacing it with fresh air.

Industrial Processes:In various industrial processes, these fans are used to exhaust fumes or introduce fresh air. They are ideal for use in industries where a large volume of air needs to be moved, such as in manufacturing plants, chemical industries, and power plants.

Ventilation Systems: Inline Fans are commonly used in ventilation systems to remove contaminated air and replace it with fresh air. They are ideal for use in commercial kitchens, bathrooms, and other areas where ventilation is required.

Centrifugal Inline Fan Service

When it comes to Centrifugal Inline Fan service, it is important to ensure that the fan is properly installed and maintained to ensure reliable operation. This may involve regular inspection and maintenance of the key components, such as the fan’s bearings and seals. If a replacement Centrifugal Inline Fan is needed, it is important to select a fan that is designed to meet the specific needs of the application. This may involve selecting a fan with a specific flow rate or pressure rating or selecting a fan that is compatible with the type of air being moved.

Proper Centrifugal Inline Fan maintenance involves following the manufacturer’s recommended maintenance schedule, which may involve regular inspections, lubrication, and other routine maintenance tasks. It is also important to ensure that the Centrifugal Inline Fan is properly aligned and mounted, in order to prevent vibration and other issues that can lead to premature wear and damage.

If a Centrifugal Inline Fan repair is needed, it is important to work with a qualified service technician who has experience with this type of fan. The technician will be able to diagnose the issue and recommend the appropriate repair or replacement options.

718.768.1600

718.768.1600